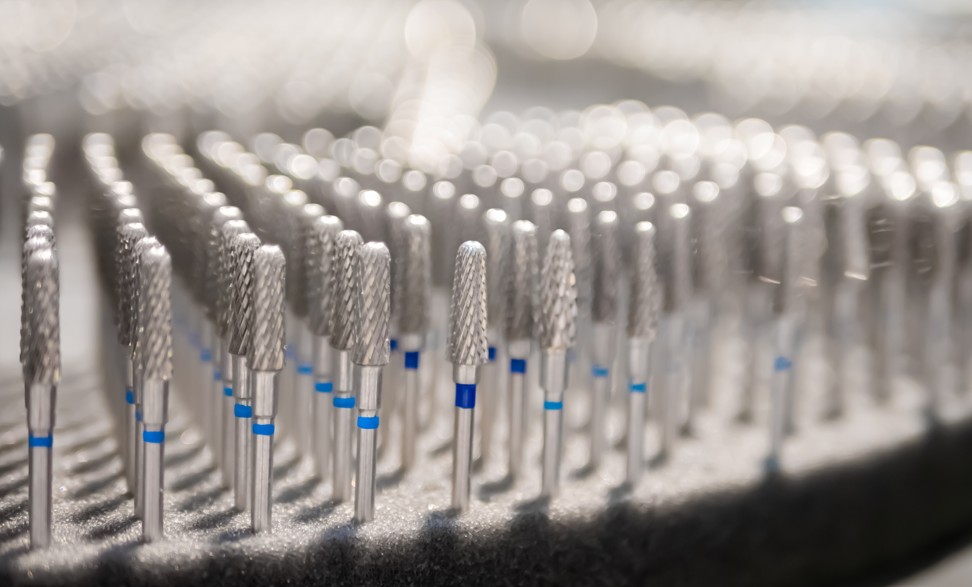

Carbide Burs are today considered essential accessories in many industries because of their efficiency, hardness, and universality. These tools are very effective for dental personnel, and business persons who make their living from metal designing to any sporting skill. It is now time to discover why carbide burs are so precious and what contribution they can give to your job.

What Are Carbide Burs?

Carbide burs are rotary cutting instruments manufactured from tungsten carbide, a material most noted for its hardness and durability. These tools provide various operations for the preparation of all sorts of materials such as metal, wood, plastics ceramics, etc. These industry tools can be used by all these people in various environments.

However, carbide burs don’t only provide long-lasting solutions but also the highest levels of precision. For instance, dentists use carbide burs in functions that require precision and detail work that must come out to be precise and smooth. Producers and enthusiasts use these tools when doing precise laser burning to engage in detailed engraving and finishing processes.

Applications Across Industries

1. Dental and Medical Use

Carbide burs are particularly popular in dental clinics since accuracy is a critical element in dentistry. The dental practice requires these robust structures to evacuate cavities to construct formation profiles and expel past fillings. The specialized design of the tool eliminates speedy and accurate cutting without producing much heat to enhance safety for all stakeholders.

2. Industrial and Manufacturing Use

Carbide burs are used in manufacturing in operations involving debarring, shaping, and cutting of metal or any hard material. Industrial applications such as manufacturing and aerospace select carbide burs because they cut at high temperatures and remain sharp.

3. Creative and Artistic Applications

Carbide burs are also useful for artists and craftsmen due to their versatility in usage. They are accurately engraved patterns on wood metal and glass household sundry of every description. Due to precise motion, these tools provide minute features that cannot be created by other devices.

Benefits of Using High-Quality Carbide Burs

Carbide burs are divided into two categories: high-quality and low-quality burs, depending on their quality, the carbide burs are tested and divided into two kinds, high-quality carbide burs, and low-quality carbide burs. Here are some key benefits:

- Durability: The material withstands long-term performance on the toughest substances available today.

- Precision: The sharp metal tips are precise in delivering clean since they offer exact results.

- Versatility: There will be many tools that are effective for a particular material or particular job.

- Efficiency: Making quick accurate cuts saves time and enables you to complete a task faster whether in designing a work or a product.

Choosing the Right Carbide Burs for Your Needs

Thus, when choosing the carbide burs, it is necessary to select the material for the job and the job description as well. These instruments come in different shapes depending on the intended use some of the burs have names such as round, flame, and cone. It is good for you to purchase a higher standard of burs today that you will need and use and save on the costs of purchasing them in the future.

Conclusion

Highest-quality carbide burs are a game changer for both working professionals as well as hobbyists. Working carbide burs are advantageous to the production of dentistry and any creative areas because they securely keep accuracy constant and keep on functioning. Carbide burs are known to be used in areas like doing complex operations in dental, as well as in etching special forms of inscription.

It is high time you accepted the light of carbide burs and realized what they mean to your work. Their tools become all the more efficient as they enable you to create better-quality products.